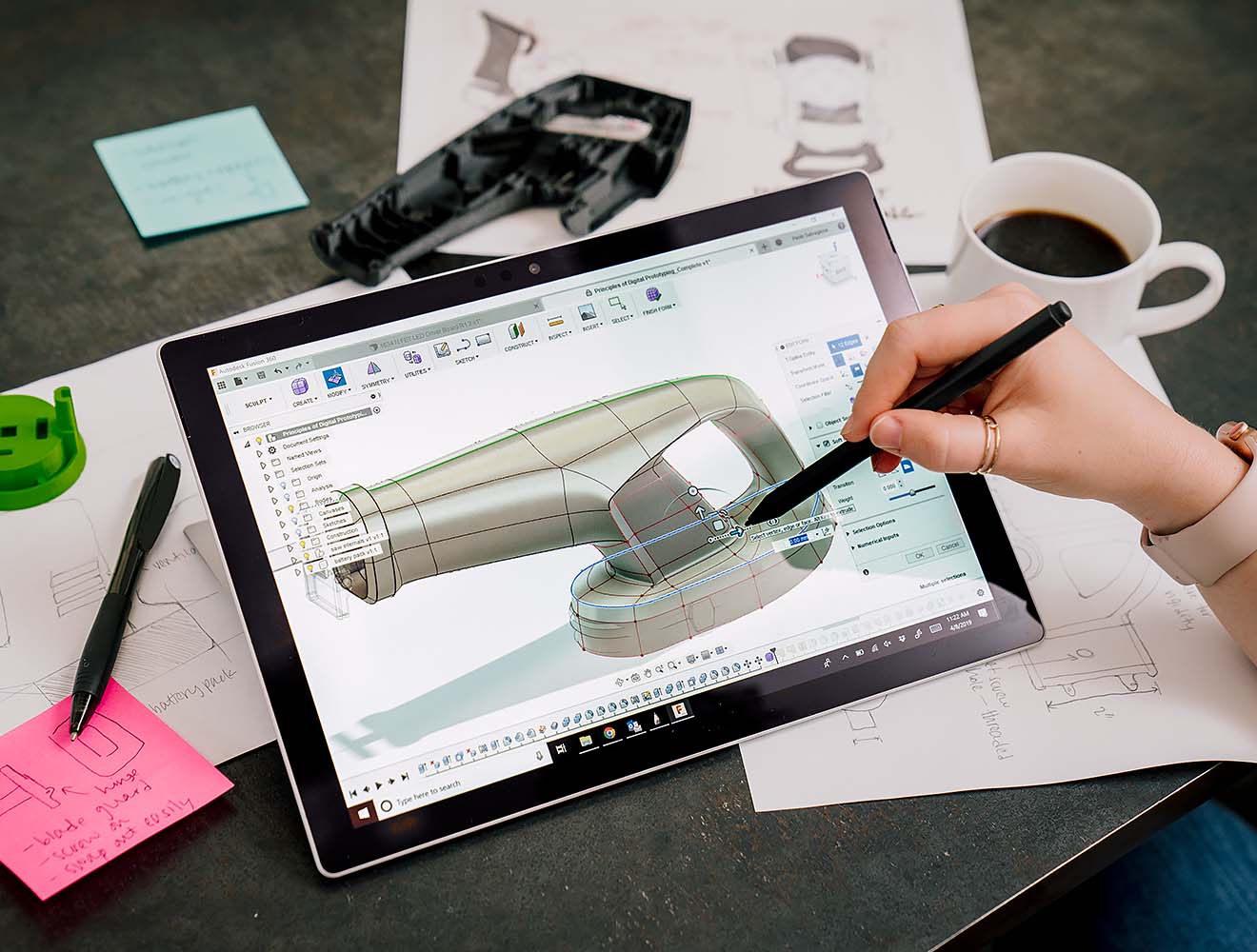

Autodesk Fusion 360: 3D Modeling Software for Beginners and Beyond

As with building any new skill, there’s typically a learning curve. This is especially true when it comes to 3D modeling. Engineering students, industrial designers, and three-dimensional (3D) modeling experts can benefit from a refresher course on 3D modeling. This beginners guide seeks to familiarize the basic process of 3D modeling and explain where to find additional resources to help designers go from dream to done in no time.

What is 3D modeling?

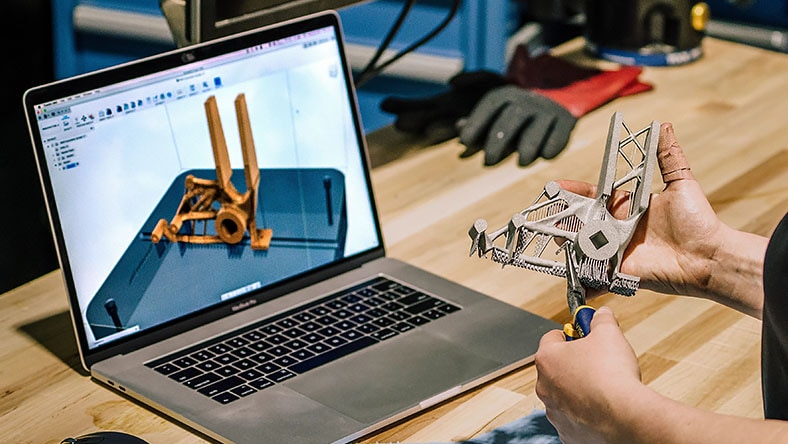

3D modeling is the process of using computer-aided design (CAD) software to develop a virtual mathematical representation or design of a desired object or part. Not to be confused with 3D printing (or additive manufacturing), which is the process of printing a physical object out of filament or another applicable material. There is a relationship between the two processes, though. Designers and engineers can export 3D models from 3D modeling software to a 3D printer to create 3D printed prototypes or final products.

3D modeling can either result in a digital or physical end product. The digital animation and film industries both use 3D modeling to bring storytelling to life on your screen. Industrial designers and engineers, however, use 3D modeling to create a digital representation of products they intend to manufacture in real life.

3D modeling advantages

3D modeling offers significant advantages over 2D drawings when using the right design software. Within CAD software, designers can create 3D models by manipulating virtual space. Modern CAD software like Autodesk Fusion 360 provides additional aides like generative design — an artificial intelligence (AI)-driven predictive method that calculates thousands of feasible 3D models.

3D models live in a digital environment. With the proper CAD software, designers and engineers can manipulate, test, and revise their designs to find the ideal balance between form, function, durability, and aesthetic appeal.

Who uses 3D modeling?

As mentioned before, 3D modeling has several different applications. Applications include video game development, testing the aerodynamics of the next space shuttle, workshopping the next successor to the Eames chair, and more.

Types of 3D modeling

There are two general types of 3D modeling: organic and hard-surface. Organic modeling is generally the digital recreation of organic or living things like trees, animals, and people. Often, organic modeling also incorporates animation. Hard-surface modeling deals with inorganic materials and static objects, such as machine parts, automobiles, or furniture. This is the type of modeling most pertinent to industrial engineers.

To learn more about 3D modeling and its applications, visit Autodesk’s 3D Modeling Software webpage.

Tools of the trade

Animators and industrial designers use similar tools when they create 3D models, such as:

- Spline: A smooth line that curves and adapts to intercept multiple defined points.

- Trim: Cuts a line to the nearest endpoint.

- Fillet: Rounds off corners within a specified radius.

- Circular pattern: Repeats selected designs around a center point.

Get started with Fusion 360: 3D modeling software for beginners

Fusion 360 is an integrated Cloud CAD solution that also provides computer-aided manufacturing (CAM), computer-aided engineering (CAE), and printed circuit board (PCB) solutions. Fusion 360 is user-friendly and provides some of the most comprehensive training materials on the internet for beginners. Below is a list of helpful links to Autodesk’s comprehensive library of tutorials and training material, such as:

- Getting Started blog content

- Self-paced Learning

- Autodesk Fusion 360 YouTube Channel

- Help Forums

In addition to training materials, Fusion 360 has an in-product chat feature where you can chat with experts or ask questions as you design your next product.

With all of these features in mind, streamline your design workflow and consider Fusion 360 for your next 3D modeling project!

Autodesk Fusion 360: More than CAD, it’s the future of design and manufacturing

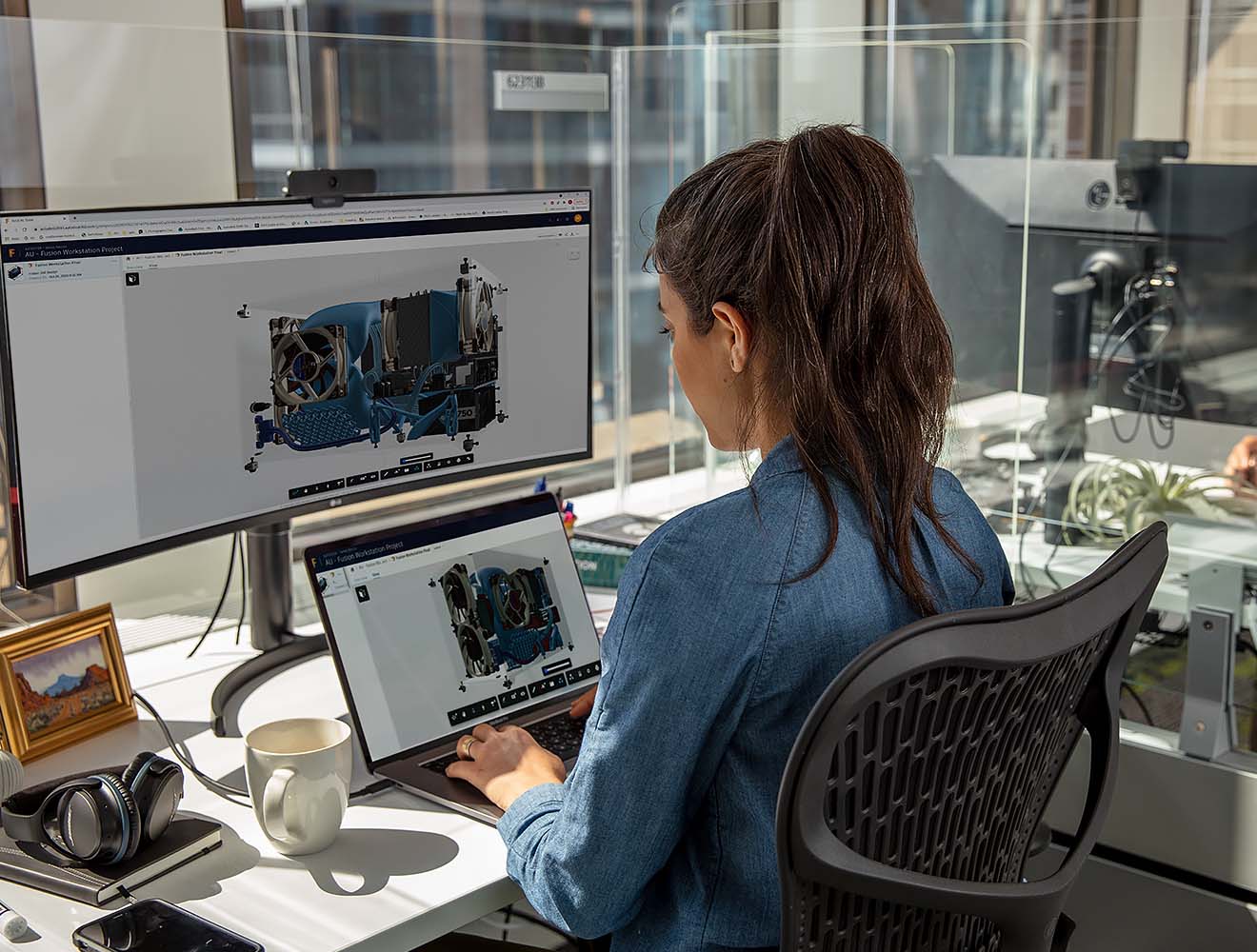

Go from design to manufacturing faster with the only all-in-one cloud CAD, CAM, CAE, and PCB product development platform, Autodesk Fusion 360.

Unify your team on one platform

Global manufacturing teams trust Fusion 360 to efficiently ideate, create, collaborate and manage their development processes in a single solution with cloud and data at the center.

Save time and costs with automated workflows

Free up resources to increase capacity with less investment in time and capital with design, electronics, and machining automation.

Autodesk Fusion 360 capabilities

Flexible 3D CAD

Autodesk Fusion 360 enables you to explore many iterations quickly with easy-to-use cloud CAD software.

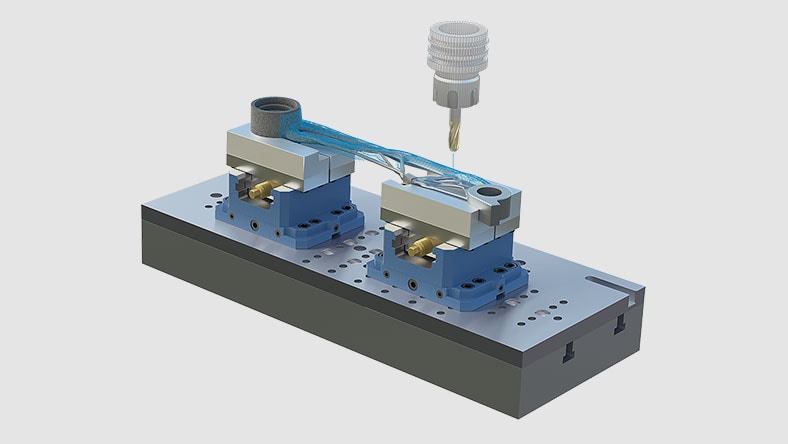

Integrated CAD/CAM

Produce high-quality CNC machined parts, and additively manufacture builds using FFF or PBF for metal 3D printing.

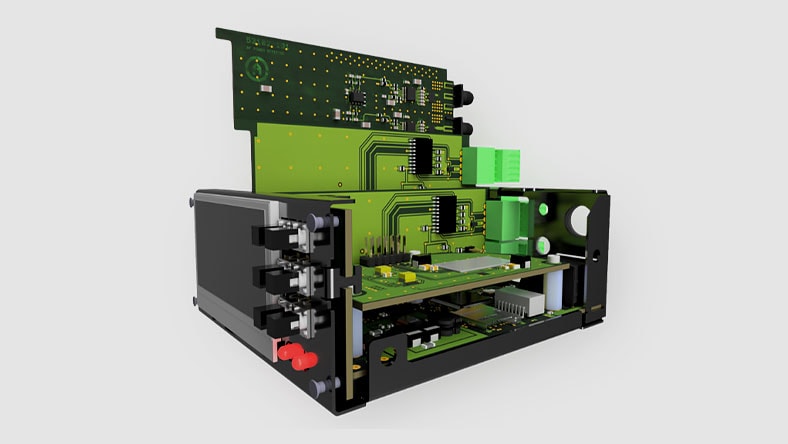

Unified PCB design

Gain all the advantages of a full-featured schematic capture, electronics design, and mechanical CAD with Autodesk Fusion 360.

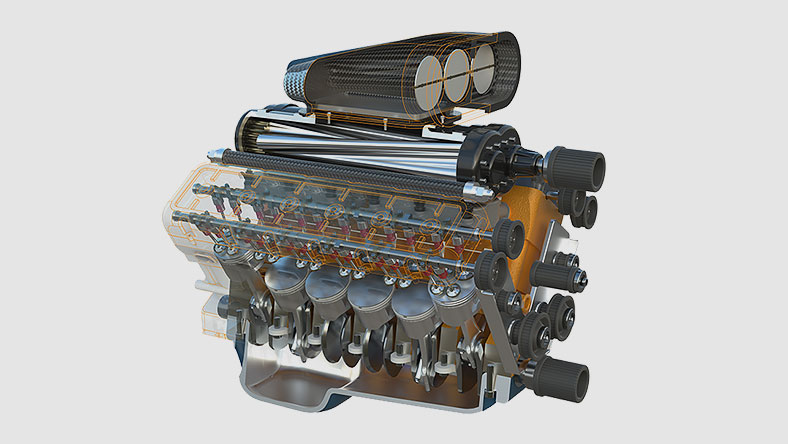

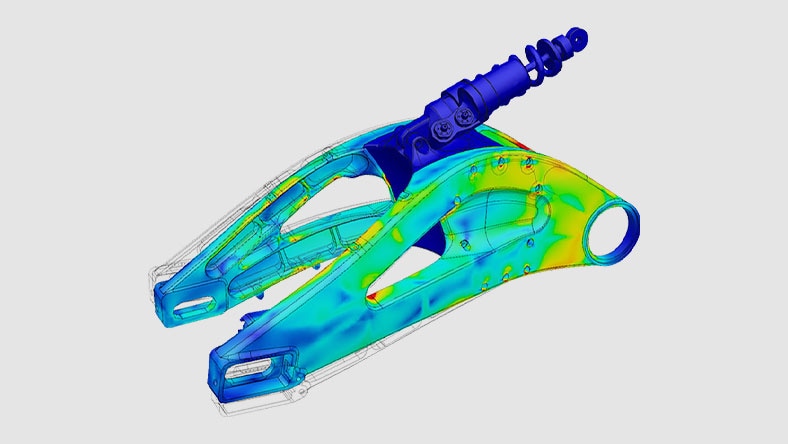

Seamless 3D simulation

Test your designs to ensure they survive real world conditions. Simulate digitally and reduce prototyping costs.

Explorative generative design tools

Explore many manufacturing-ready outcomes meeting your design specifications through generative design.

Instant-on data management

Use integrated cloud collaboration tools to bring teams together and manage product data.

«Fusion 360 is recognized as the best professional cloud product design and manufacturing software platform on G2.»

– 4.5/5 rating, 400+ reviews

Trusted by 1.2 million customers, including:

What you can do with Autodesk Fusion 360

Flexible 3D modeling and design

Use direct, surface, parametric, mesh, or freeform modeling.

Interactive assemblies

Detailed visualizations of complex products with exploded views and animations.

Sheet metal part creation

Design and engineer products to ensure aesthetics, form, fit, and function.

Innovative generative design

Explore, design, quote, and fabricate faster with automation tools.

Unified electronics and PCB design

Comprehensive electronics and PCB engineering tools.

Push-button SPICE simulation

Easy SPICE (Simulation Program with Integrated Circuit Emphasis) setup.

Unlimited hierarchical schematic capture

Support for 16-layer PCB systems.

Integrated CAD and CAM

Additive manufacturing, 2 & 3-axis, 3+2, 4 & 5-axis milling and more.

Cloud collaboration and data management

Connect teams, communicate in real-time, and manage projects with global collaboration.

Photo-realistic rendering and documentation

Annotate, dimension, and document models with real-life rendering technology.

FEA verification, test, and simulation

Topology and shape optimization with cloud-based machine learning and AI.

Why professionals use Autodesk Fusion 360

Design and Manufacturing Teams Machinists Electronics Engineers Industrial Designers Mechanical Engineers

One product development tool for teams

Global design and manufacturing teams rely on Autodesk Fusion 360 to efficiently ideate, create, collaborate, and manage their development processes in a single solution with cloud and data at the center. “With Fusion 360, we can execute several different functions within one package, and that has been the most important thing for us. We don’t have to use Rhino for sculpting or SolidWorks for mechanical design. We can do that with the same software and actually all work on the same file at the same time. It’s a huge benefit.” — Carl Budd, Engineering Manager, Moose Toys

3D CAD/CAM for machinists

Machine quality parts faster with Autodesk Fusion 360. Reduce cycle times to improve your bottom line with integrated 3D CAD/CAM software. “Our business has grown by 400% in just over a year, and we can attribute a lot of this growth to Fusion 360. Fusion 360 is a CAM system that is made for making parts.” — Conrad Nerc, Nerc Precision Engineering

3D PCB design for electronics engineers

Gain access to fully functional, comprehensive PCB design. Unify MCAD and ECAD workflows in one end-to-end solution for electronic engineers with Autodesk Fusion 360. “We merge electronics with mechanics. There are very few software firms that are capable of doing this. Autodesk Fusion 360 was therefore the logical choice, as they connect all departments, electronics, and mechanics for us.” —Mario Tousek, Managing Director, tousek

3D prototyping for industrial designers

Speed up ideation and connect with engineering teams faster. Industrial Designers use Autodesk Fusion 360 to accelerate design, testing, fabrication, and collaboration with 3D prototyping. “My prior approach to modeling was very time-consuming. With Fusion 360, I can spend more time being creative and thinking about the concept more—rather than getting bogged down with little details.” — Allan Williams, Independent Designer

3D modeling for mechanical engineers

Simultaneously generate multiple 3D design models with Autodesk Fusion 360, allowing mechanical engineers to solve challenges faster and ensure their products will survive real world conditions. “When it comes to Fusion 360, it’s the whole concept of the ability to share models, create assemblies in one file, see all the component dependencies, doing all your motion studies, and figuring out interfaces in one place.”— Steve Milanoski, Head of Advanced Manufacturing, Romar Engineering

При подготовке материала использовались источники:

https://www.autodesk.com/products/fusion-360/blog/autodesk-fusion-360-3d-modeling-software-for-beginners-and-beyond/

https://www.autodesk.com/products/fusion-360/overview